Emergency Hotline

If you need to report an emergency, you can contact Seneca Resources 24 hours a day, 7 days a week at 1-800-526-2608 in Pennsylvania.

Landowner Questions

For landowner inquires or concerns, please contact The Land Department at 412-548-2600 or at landadmin@srcx.com.

Fueling a Cleaner Tomorrow

Seneca Resources has a long history of environmental stewardship, safety, innovation, transparency, and community involvement. As an active exploration and production company for over 100 years, Seneca and its predecessor companies have worked alongside regulatory agencies and community leaders to foster a culture of respect for and protection of the environment. Our above-and-beyond stewardship includes 100% responsibly sourced gas designations, innovative technology, state-of-the-art water management, and a robust biodiversity program.

Committed to Reducing Emissions

Seneca is committed to further reducing its already low methane intensity by continuing to develop and incorporate best-in-class controls and monitoring procedures, including:

- Continuous monitoring devices and aerial methane detection surveys

- Natural gas pneumatic device replacements

- Enhanced leak detection & repair program

- Techniques & equipment to reduce emissions during well unloading

Seneca monitors and reports on specific types of air emissions that are relevant to business operations as required by state or federal regulations. Emissions management and monitoring protocols are regularly reviewed. We also participate in several voluntary methane emission reduction programs that seek to reduce methane and other emissions beyond regulatory requirements by implementing best practices.

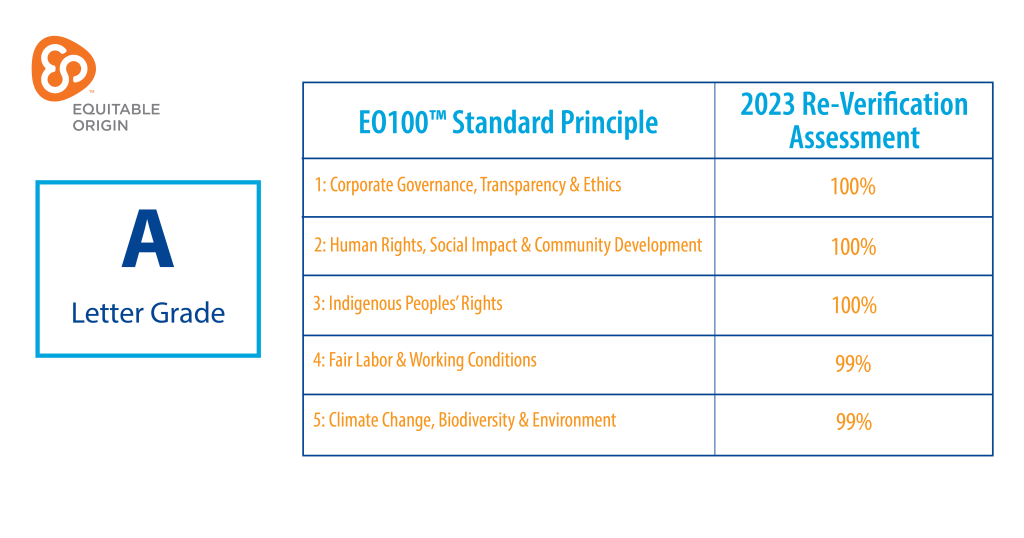

100% Certified Natural Gas

In December 2021, Seneca achieved certification of 100% of its Appalachian production, over 1 billion cubic feet of gross production, under Equitable Origin’s EO100™ Standard for Responsible Energy Development, which includes five principles that encompass the entire spectrum of ESG:

• Corporate Governance, Transparency and Ethics;

• Human Rights, Social Impact and Community Development;

• Indigenous People’s Rights;

• Fair Labor and Working Conditions; and

• Climate Change, Biodiversity and Environment.

In 2023, Seneca completed its annual re-verification process, which is required to maintain Equitable Origin certification, and received an “A” grade under the EO100™ Standard. To achieve this “A” grade, Seneca demonstrated a score of 98% or higher across all five of the standard’s principles:

In August 2022, Seneca achieved certification of 100% of its Appalachian natural gas production under the MiQ Standard for Methane Emissions Performance at the highest certification level, an “A” grade. The MiQ Standard is an independent framework for assessing methane emissions and practices for oil and gas facilities and is a credible way to differentiate natural gas production based on methane emissions. The score is based on how well operators deploy integrated technologies to detect, measure, and abate emissions. It also includes a detailed assessment of policies and work practices to prevent future methane emissions.

In August 2022, Seneca achieved certification of 100% of its Appalachian natural gas production under the MiQ Standard for Methane Emissions Performance at the highest certification level, an “A” grade. The MiQ Standard is an independent framework for assessing methane emissions and practices for oil and gas facilities and is a credible way to differentiate natural gas production based on methane emissions. The score is based on how well operators deploy integrated technologies to detect, measure, and abate emissions. It also includes a detailed assessment of policies and work practices to prevent future methane emissions.

Greenhouse Gas Emissions

Seneca is committed to reducing methane emissions and continues to develop best-in-class emissions controls to reduce the methane intensity of our operations. We have set a target of a 40% reduction in methane intensity from our baseline 2020 year. We continue making significant progress toward our target by implementing a natural gas pneumatics replacement program, applying best practices to reduce venting throughout our operations, and leveraging our Sustainable Development Team to implement innovative ways to minimize emissions.

EPA Methane Challenge member since 2018:

A program with specific best management practices that Seneca Resources has committed to implementing to reduce or eliminate methane emissions.

API Environmental Partnership member since 2018:

An industry-led organization to share best practices and new technology information relating to emissions controls with commitments to implement those controls.

Our Nation's Energy Future (ONE Future) Coalition

In August 2021, National Fuel and its subsidiaries joined Our Nation’s Energy Future (ONE Future) Coalition. This Coalition is comprised of natural gas companies that are working to voluntarily reduce methane emissions across the value chain to 1%, or less. Additionally, National Fuel has committed to the Gas Technology Institute’s (GTI) Project Veritas as an Initiative Partner. Project Veritas aims to expedite methane emission reductions by developing transparent technical protocols for calculating methane emission methodologies and intensities across the natural gas value chain.

Utilizing Field Gas

Seneca was the first company in the Appalachian Basin to use a bi-fuel drilling rig, and has since expanded that use to include bi-fuel frac pumps that use field gas in lieu of diesel as a fuel source. Seneca estimates that during these operations, it can run on field gas about 60% of the time, which drives significant reductions in emissions. The technology reduces energy and extends the life of equipment.

Green Completions

Seneca employs “green completion” techniques on nearly all Marcellus and Utica Shale development wells. Green completions avoid venting and flaring during a well’s initial production whenever possible to minimize emissions. 100% of our development wells in fiscal 2019 employed green completions.

Incorporating Innovative Technology

Seneca is always looking for new ways to incorporate green technology into its operations. In 2022, we installed a small solar farm at a producing pad in Elk County, PA, to power a compressed air system that runs the pad’s pneumatic devices. The pad is 100% solar-powered during optimal conditions.

Water Management

Seneca prides itself on being an industry leader in managing water assets. For calendar 2021, based on a survey of environmental performance conducted by The American Exploration and Production Council (“AXPC”) – a national trade association representing the largest independent oil and natural gas exploration and production companies in the United States – Seneca Resources ranked 2nd best out of 25 companies for our recycled water rate.

In 2014, Seneca formed its own water logistics company, Highland Field Services, LLC (“Highland”), to manage the sourcing, handling, and recycling of fluids generated by and used in its Appalachian operations. Since then, Highland has invested over $90 million in water infrastructure in Pennsylvania, including storage and treatment facilities, on-pad tanks and containment vessels, injection wells, and a network of water distribution pipelines.

Recycled water

Seneca Resources follows a strict “zero surface discharge” policy and works diligently to treat, recycle, and reuse all flowback and produced water. In calendar year 2021, Highland Field Services recycled over 90% of Seneca’s produced fluids, or 9.45 million barrels, plus an additional 1.65 million barrels of fluids that were generated by and received from third-party operators.

Reduced Environmental Footprint

Highland manages the movement of approximately 850,000 barrels of fluid every month. In the Western Development Area, approximately 89% is pumped through Highland’s pipeline distribution system to deliver fluids from storage facilities directly to Seneca’s Marcellus and Utica development pads. As a result, Seneca was able to avoid an estimated 74,000 truck trips in 2021, eliminating the associated air emissions and reducing the impact on local roads and public infrastructure. Highland is working to replicate this model in the Eastern Development Area.

Land & Biodiversity

Containment Management

Seneca has developed its own series of containment management best practices. Primary containment, such as steel tanks, bins, and containers, are always placed within secondary containment with a physical barrier surrounding each. Additional steps taken include:

- Using high-grade liners and rig mats at every pad, long before mandated by PaDEP

- Conducting rigorous daily inspections and maintenance to ensure the liner is intact

Surface Footprint Neutral

Seneca is committed to minimizing impacts on biodiversity and often goes beyond regulatory requirements to understand, maintain, and increase biodiversity throughout our operating area. Our Surface Footprint Neutral Program works to restore, enhance, or protect biodiversity by returning one acre of land to the environment for every acre disturbed by our operations. Seneca works with state agencies and local conservation groups to determine strategies for biodiversity projects and find ways to re-purpose stone, trees, root wads, and other natural materials displaced by well pad and road construction.